Shower Cabins

Aluminium is a popular material used in the manufacturing of shower cabins, due to its durability, strength, and corrosion resistance. Aluminium shower cabins are typically made from extruded aluminium profiles, which are cut and assembled to create the frame and structure of the cabin.

One of the primary benefits of using aluminium in shower cabins is its resistance to corrosion and rust. Shower cabins are constantly exposed to moisture and humidity, which can cause steel or other metals to corrode over time. Aluminium, on the other hand, is highly resistant to corrosion and can withstand exposure to water and humidity without deteriorating.

Aluminium shower cabins are also lightweight and easy to assemble, which makes them a popular choice for manufacturers and installers. The extrusion process used to create aluminium profiles allows for precise customization of the frame and structure, which can be tailored to specific shower cabin designs.

In addition, aluminium shower cabins offer a sleek and modern look, which is desirable for many homeowners and interior designers. Aluminium profiles can be finished with a variety of coatings or finishes, including anodizing or powder coating, which can provide additional protection and enhance their aesthetic appeal.

Overall, the use of aluminium in shower cabins offers a durable and low-maintenance solution that is resistant to corrosion and rust. Aluminium shower cabins can be customized to meet specific design requirements, and offer a sleek and modern look that is popular with homeowners and interior designers alike.

Aluminum Profiles for Shower Cabins:

T-Profile: T-Profiles are frequently used to link glass panels in shower cabins, where they serve the dual purpose of providing stability and support.

Advantages: The design of the T-shape enables a secure connection between the panels, which enhances the overall structural integrity of the product.

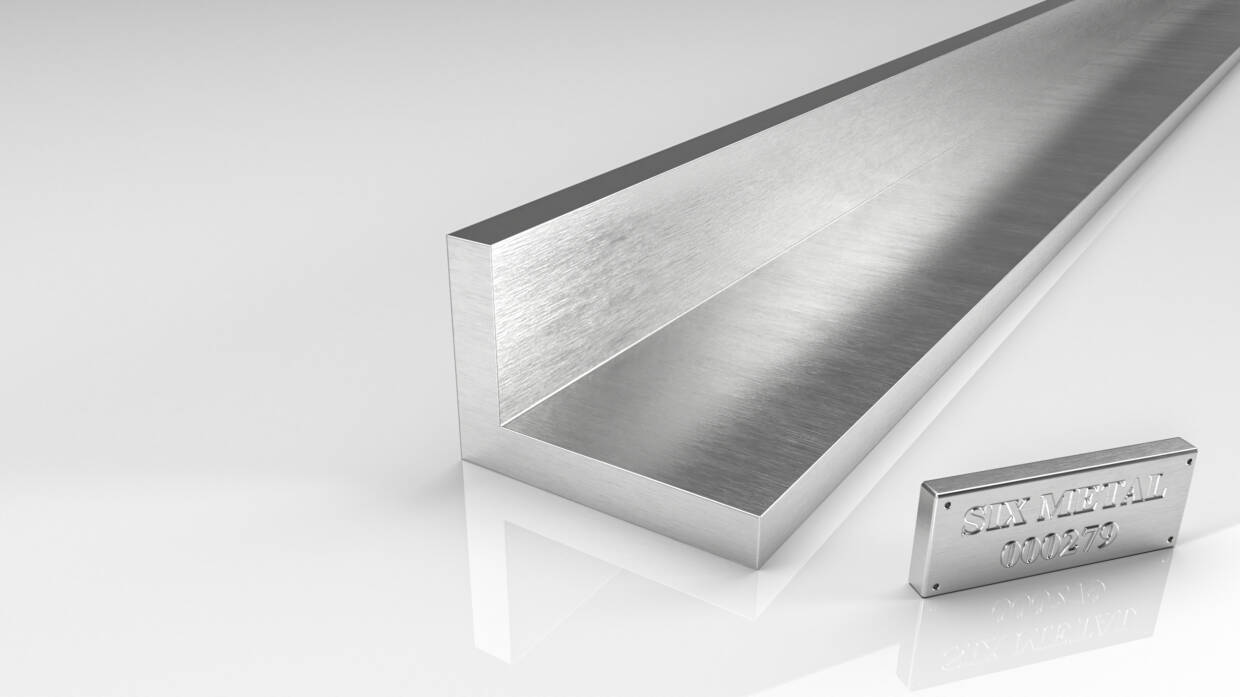

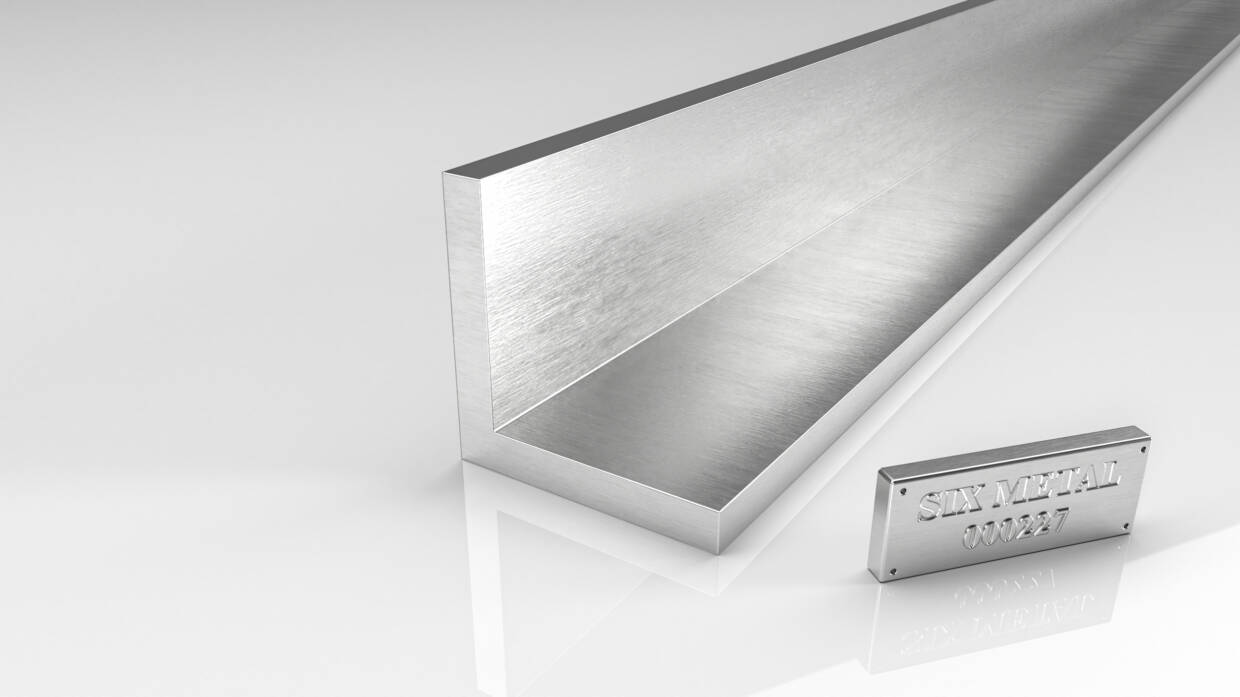

L-Profile:

Application: In shower stalls, L-profiles are frequently used to attach and lock glass panels to the walls or the floor.

Advantages: The L-shaped profile provides a sturdy mounting option for the glass panels, maintaining the panels' stability and reducing water leakage.

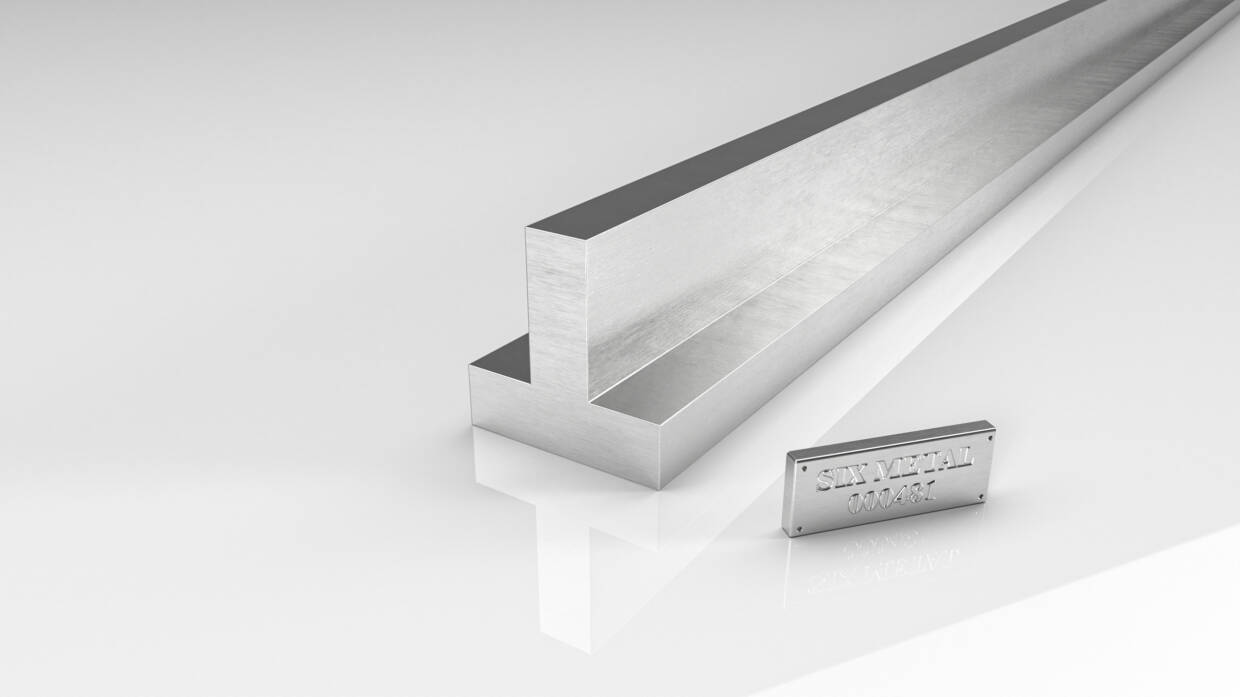

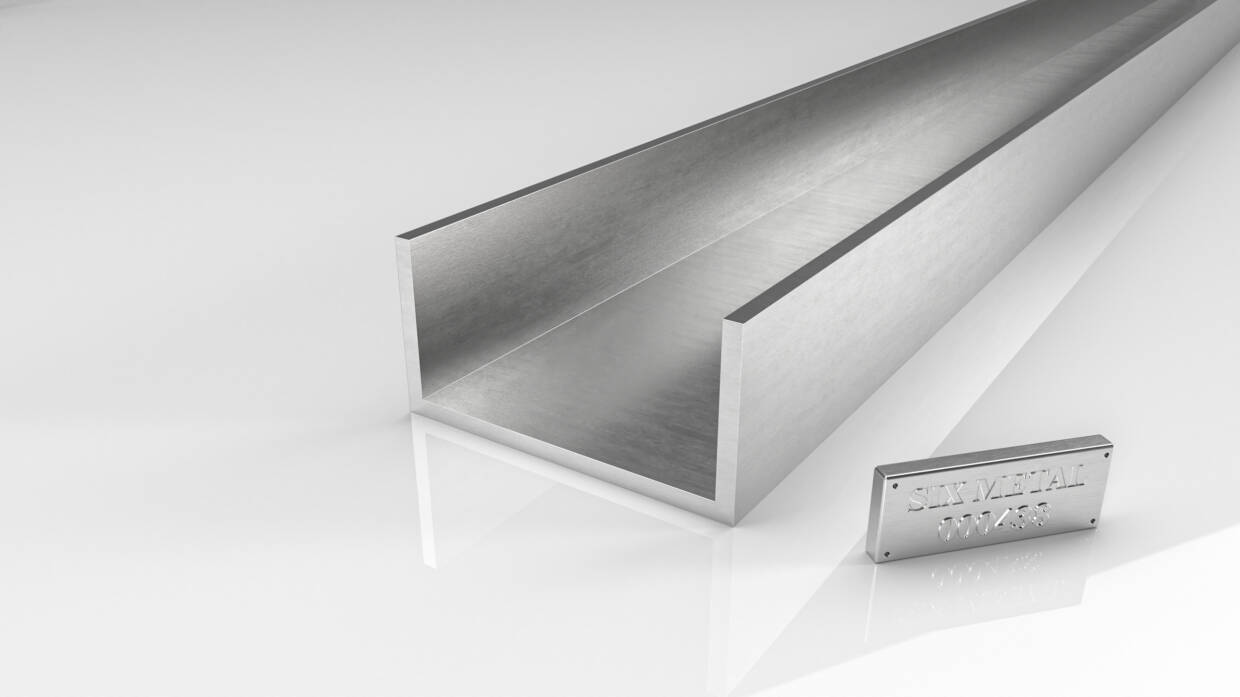

U-Profile:

Application: U-profiles are utilized in shower stalls to encircle and secure the edges of glass panels.

Advantages: These profiles not only give the glass panels the support they need, but they can also act as a sealing point by including rubber inserts or gaskets to prevent water from leaking through.

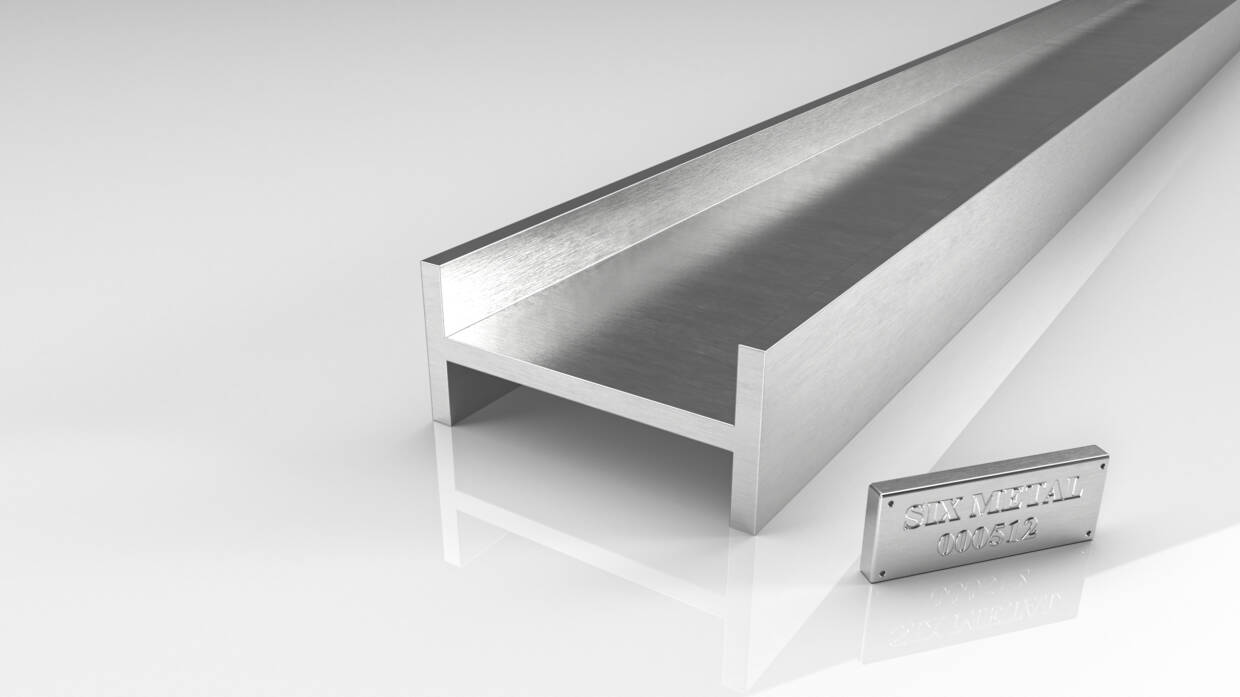

H-Profile:

Usage: H-profiles are used to establish a gap between glass panels, which allows for a secure connection in shower stalls and other similar enclosures.

Advantages: The H-shaped form offers a reliable and aesthetically beautiful connection while still preserving the structural integrity of the structure.

Handle Profile:

Usage: Handle profiles are designed for easy door operation in shower stalls and other similar enclosures.

Advantages: These profiles are available in a wide range of forms and sizes, making it possible to find one that offers a pleasant and ergonomic grasp when opening and closing the shower door.

Seal Profile:

Usage: In order to stop water from escaping between the shower door and the glass panels, seal profiles are installed between them.

Advantages: Constructed from elastic materials, these profiles produce a watertight seal, which improves the overall functioning and performance of the shower enclosure as a whole.

For more detailed and accurate information, you can check our catalogue or directly contact us.