Packaging plays a crucial role in the transportation and delivery of products. Proper packaging ensures that the products remain intact and free from any damages during transit. Packaging also helps to identify the product and provide essential information such as the contents of the package, destination, and handling instructions. In this article, we will be focusing on Six Aluminum’s packaging process and how it contributes to the safe delivery of their products.

Importance of Proper Packaging in Means of Delivery

Proper packaging is essential in means of delivery as it ensures that the products reach their destination safely and in good condition. Here are some of the reasons why proper packaging is crucial in means of delivery:

- Protects Products: Proper packaging helps to protect the products from any damages that may occur during transportation. This is especially important for fragile products that require extra care during handling and transportation.

- Identifies Products: Packaging helps to identify the product and provide essential information such as the contents of the package, destination, and handling instructions. This ensures that the product reaches its intended recipient and is handled appropriately.

- Improves Brand Image: Proper packaging can improve the brand image by providing a positive impression of the product and the company. Customers are more likely to recommend a company that provides good packaging and delivery services.

Six Aluminum’s Packaging Process for Aluminum Profiles

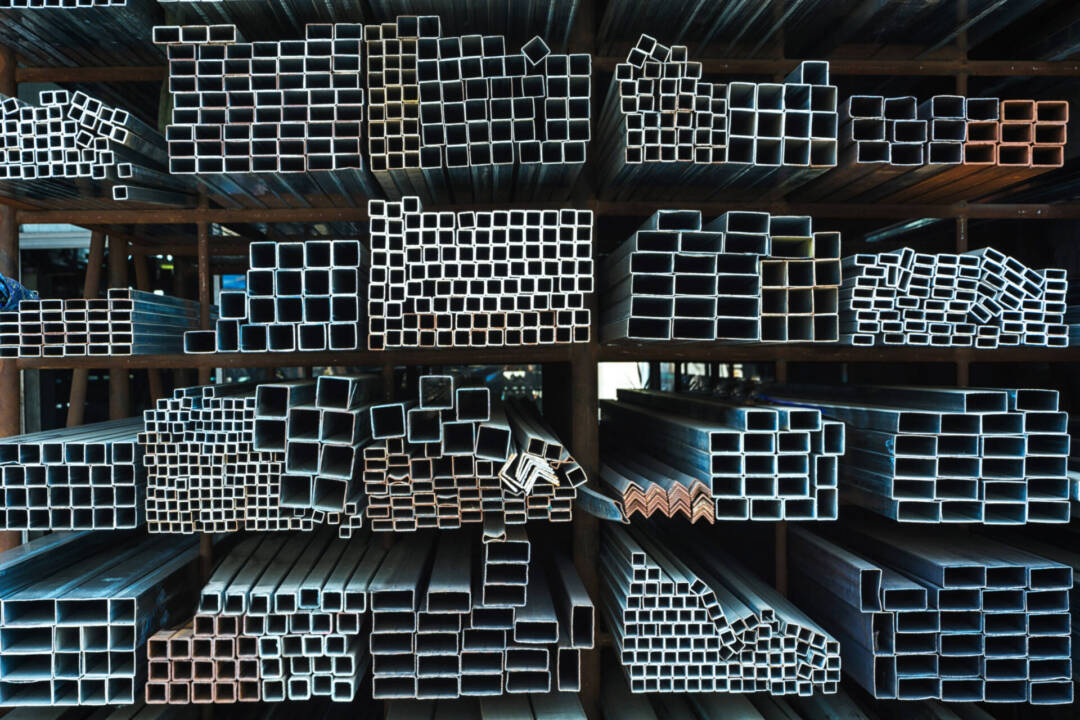

Six Aluminum takes great care in packaging their aluminum profiles to ensure that they retain their shape and surface properties during transport and until delivery to their customers. Six Aluminum has adopted necessary measures and practices to guarantee the sturdy packaging of their products. Here are some of the packaging practices Six Aluminum follows:

- Material Selection: Six Aluminum uses high-quality packaging materials that are strong and durable, such as corrugated cardboard boxes and pallets. The packaging material used for aluminum profiles must be sturdy enough to protect the product during transportation.

- Designing: Six Aluminum’s design team creates custom packaging solutions that fit the specific requirements of each aluminum profile shipment. The packaging design must be appropriate for the product being shipped.

- Quality Control: Six Aluminum has a dedicated team of quality control experts who ensure that all packaging materials and designs meet the highest quality standards. The quality control process involves rigorous testing and inspection of the packaging to ensure that it can withstand the stresses of transportation.

- Padding: To prevent any damage to the product, Six Aluminum pads the aluminum profiles using foam inserts or bubble wrap. This provides extra protection to the product during transportation.

- Reinforcement: Six Aluminum reinforces the packaging by adding additional cardboard inserts or wood planks to the package. This ensures that the product is well protected and can withstand any shocks during transit.

- Strapping: Six Aluminum straps the aluminum profiles to the pallet or inside the box to prevent movement during transportation. This prevents the product from shifting inside the packaging and reduces the risk of any damages during transit.

- Labeling: Six Aluminum labels the packages with essential information, such as the contents of the package, destination, and handling instructions. This ensures that the product reaches its intended recipient and is handled appropriately.

Benefits of Six Aluminum’s Packaging Process

Six Aluminum’s packaging process for aluminum profiles has several benefits, including:

- Ensuring Safe Delivery: Six Aluminum’s packaging process ensures that the aluminum profiles reach their destination safely and in good condition. The packaging provides extra protection to the product during transportation and reduces the risk of any damages during transit.

- Improving Brand Image: Six Aluminum’s packaging process can improve the brand image by providing a positive impression of the product and the company. Customers are more likely to recommend Six Aluminum to others due to their quality packaging and delivery services.

- Customized Solutions: Six Aluminum’s design team creates custom packaging solutions that fit the specific requirements of each aluminum profile shipment. This ensures that the packaging is appropriate for the product being shipped and provides maximum protection during transit.

- Reduced Costs: Six Aluminum’s packaging process reduces the risk of damages during transit, which can result in costly returns or replacements. By ensuring safe delivery, Six Aluminum can reduce the overall costs associated with transportation and logistics.

- Eco-Friendly: Six Aluminum’s packaging materials are eco-friendly and can be recycled. This demonstrates Six Aluminum’s commitment to sustainability and reducing their environmental impact.

Conclusion

In conclusion, proper packaging is essential in means of delivery as it ensures that the products reach their destination safely and in good condition. Six Aluminum takes great care in packaging their aluminum profiles to ensure that they retain their shape and surface properties during transport and until delivery to their customers. Six Aluminum’s packaging process includes material selection, designing, quality control, padding, reinforcement, strapping, and labeling. The benefits of Six Aluminum’s packaging process include ensuring safe delivery, improving brand image, customized solutions, reduced costs, and eco-friendliness. By following these packaging practices, Six Aluminum demonstrates their commitment to providing quality packaging and delivery services to their customers.