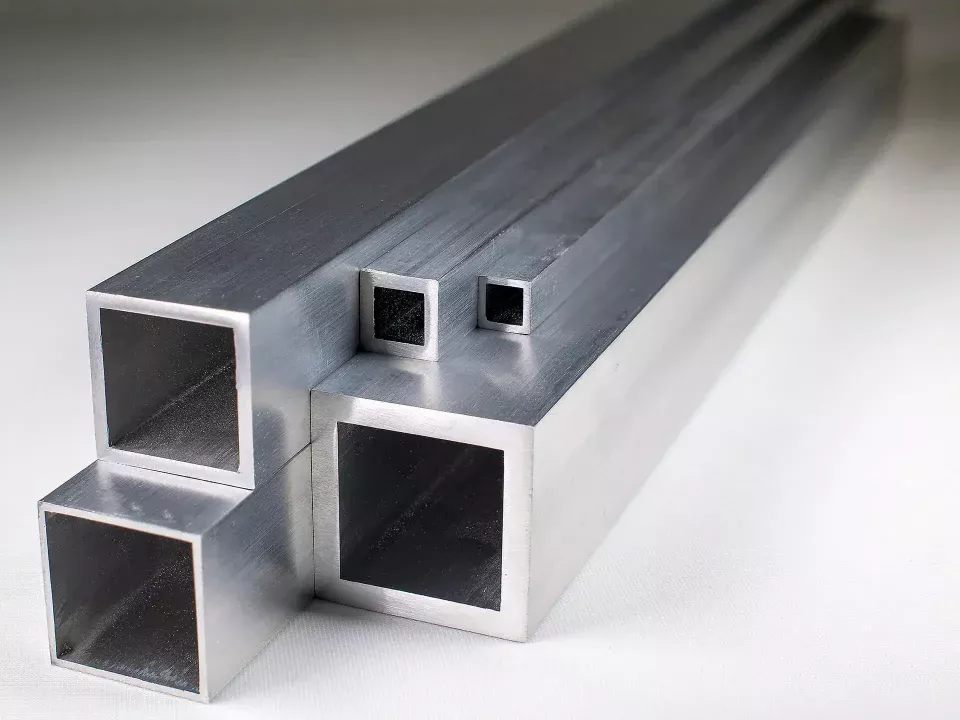

Aluminum square tubes are a popular choice for construction projects due to their durability, strength, and lightweight properties. Compared to other materials such as steel or iron, aluminum is corrosion-resistant, making it ideal for outdoor structures that are exposed to the elements.

Another benefit of using aluminum square tubes is their flexibility. Aluminum can be easily formed into different shapes and sizes, making it a versatile material that can be used in a variety of construction projects. Additionally, aluminum square tubes are easy to work with, and they can be cut and welded to fit specific project requirements.

Aluminum is also an eco-friendly choice for construction projects. It is a highly recyclable material, meaning that it can be repurposed and reused again and again, reducing waste and saving resources. Furthermore, aluminum production requires less energy than other materials, making it a more sustainable choice for construction projects.

Finally, aluminum square tubes offer a sleek and modern look that can enhance the aesthetic appeal of any construction project. Their smooth and shiny surface finish can add a touch of elegance to any design, making them a popular choice for architectural projects.

In conclusion, aluminum square tubes offer numerous benefits for construction projects, including durability, flexibility, eco-friendliness, and aesthetic appeal. Their unique properties make them a versatile and practical choice for a variety of construction projects.

Choosing the Right Aluminum Square Tube for Your Project

When it comes to selecting the right aluminum square tube for your construction project, there are a few key factors to consider. Here are some of the most important considerations:

Alloy type: Aluminum square tubes come in a variety of different alloy types, each with its own unique properties. Some of the most common alloy types include 6061, 6063, and 2024. The alloy type you choose will depend on the specific requirements of your project.

Size and shape: Aluminum square tubes come in a variety of sizes and shapes, and it’s important to choose the right one for your project. Consider the dimensions of the structure you’re building and choose a tube that will fit those specifications.

Strength: Depending on the application, you may need an aluminum square tube with a high level of strength. Make sure to choose a tube that has the necessary strength properties to withstand the loads and stresses it will be exposed to.

Surface finish: Aluminum square tubes can be finished in a variety of ways, including brushed, polished, or anodized. Consider the desired aesthetic of your project and choose a surface finish that will complement it.

Cost: Finally, consider the cost of the aluminum square tube. While aluminum is generally less expensive than other materials such as steel or iron, the cost can vary depending on the alloy type and other factors. Make sure to choose a tube that fits within your budget.

By considering these factors, you can choose the right aluminum square tube for your construction project and ensure its success.

How to Cut and Weld Aluminum Square Tubes

Cutting and welding aluminum square tubes can be challenging, but with the right tools and techniques, it can be done successfully. Here are some tips for cutting and welding aluminum square tubes:

Cutting:

Choose the right cutting tool: Aluminum can be cut using a variety of cutting tools, including a hacksaw, circular saw, or jigsaw. Choose the tool that will provide the cleanest and most precise cut for your specific project.

Use the correct blade: Make sure to use a blade that is designed for cutting aluminum. A blade with carbide teeth or a high-speed steel blade will work best.

Lubricate the blade: To prevent the blade from overheating and to ensure a clean cut, apply a lubricant.

Mark the cut line: Use a ruler or measuring tape to mark the cut line on the aluminum square tube. This will ensure a precise cut and minimize waste.

Secure the tube: Use a clamp or vise to secure the aluminum square tube in place before cutting. This will prevent the tube from moving or vibrating during the cutting process.

Welding:

Choose the right welding method: There are several methods for welding aluminum square tubes, including MIG, TIG, and Stick welding. Choose the method that is best suited for your specific project.

Use the correct filler rod: Aluminum filler rods are available in a variety of alloys and sizes. Choose the correct filler rod that matches the alloy type of your aluminum square tube.

Prepare the surfaces: Before welding, make sure to clean and prepare the surfaces that will be joined. This will ensure a strong and durable weld.

Use a proper welding technique: Welding aluminum square tubes requires a different technique than welding other metals. The key is to use a low heat setting and move the welding torch quickly to prevent the aluminum from melting.

Practice first: If you’re new to welding aluminum square tubes, it’s important to practice on scrap pieces before starting your project. This will help you get a feel for the welding process and ensure that your welds are strong and durable.

In conclusion, cutting and welding aluminum square tubes requires careful preparation, the right tools, and proper technique. By following these tips, you can successfully cut and weld aluminum square tubes for your construction project.