Aluminum flat tubes are widely used in the automotive industry due to their numerous benefits. This article will discuss the various applications of aluminum flat tubes in automotive and the advantages they offer.

Radiator Tubes

Aluminum flat tubes are commonly used in the construction of radiator tubes. They are lightweight, corrosion-resistant, and have excellent heat dissipation properties, making them an ideal material for this application.

Engine Cooling Systems

Aluminum flat tubes are also used in the construction of engine cooling systems. They are lightweight and have excellent heat dissipation properties, making them an ideal material for this application. They are often used for components such as heat exchangers and oil coolers.

Air Conditioning Systems

Aluminum flat tubes are also used in the construction of air conditioning systems. They are lightweight, corrosion-resistant, and have excellent heat dissipation properties, making them an ideal material for this application.

Fuel Systems

Aluminum flat tubes are used in the construction of fuel systems in vehicles. They are corrosion-resistant and can withstand exposure to chemicals, making them ideal for this application.

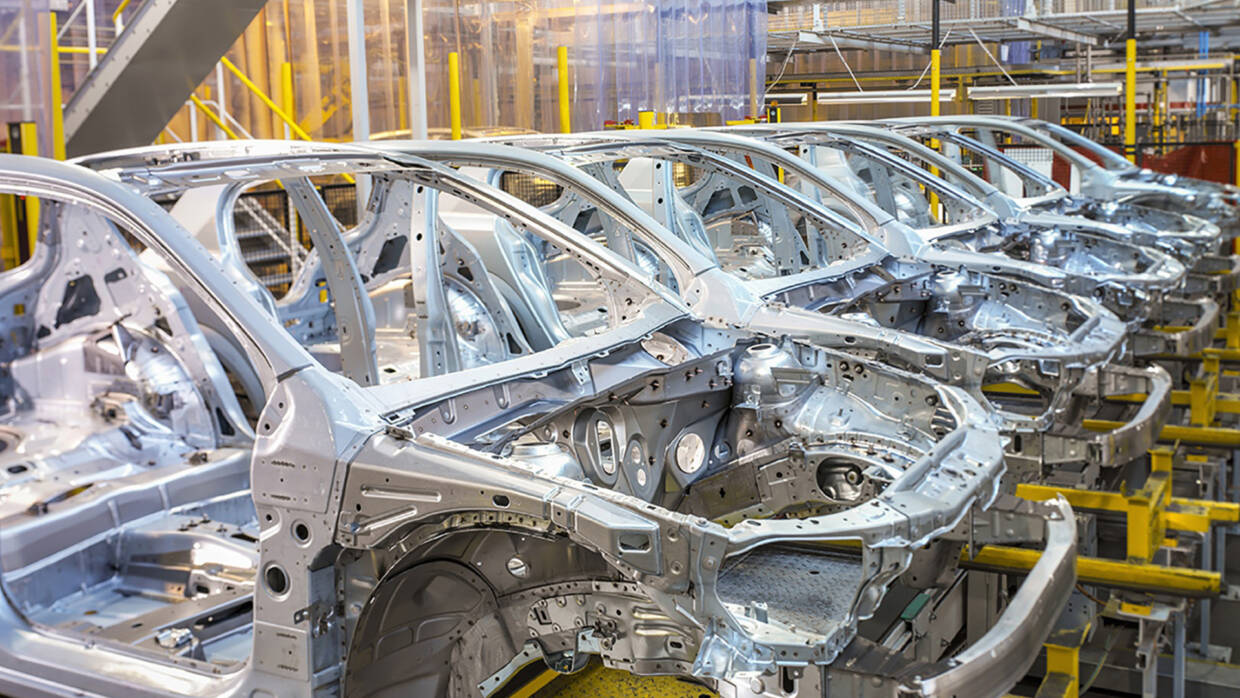

Chassis and Suspension

Aluminum flat tubes can be used as structural elements in vehicle chassis and suspension systems. They are strong, lightweight, and have excellent resistance to corrosion, making them an ideal material for this application.

Exterior Trim

Aluminum flat tubes are also used for exterior trim in vehicles, providing a sleek, modern look. They can be used for features such as grilles, trim strips, and door handles.

Overall, aluminum flat tubes offer numerous advantages for the automotive industry. Their lightweight, corrosion resistance, heat dissipation properties, and versatility make them ideal for a variety of applications, including radiator tubes, engine cooling systems, air conditioning systems, fuel systems, chassis and suspension, and exterior trim.